Products

Aluminum corrugated board

Classification:

Aluminum honeycomb plate

Key words:

Characteristics of aluminum corrugated board

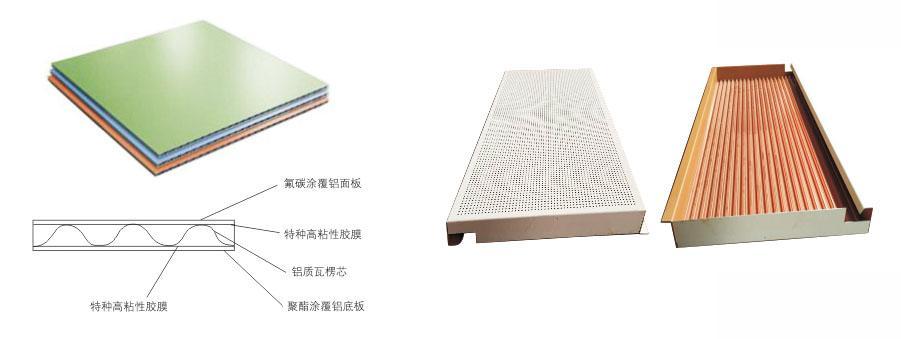

Aluminum corrugated plate is a kind of aluminum alloy composite plate with corrugated core between the panel and the bottom plate. It is an advanced technology, the latest technology research and development products, retaining the advantages of aluminum honeycomb plate, improving the characteristics of aluminum-plastic composite plate, the application field is very wide.

1. The smoothness and compression resistance can maintain its superior smoothness because it improves the distortion and bending of the metal ordinary aluminum veneer.

2. Weather resistance can prevent the corrosion of the climate by surface treatment of PVDF to the aluminium plate, so it can maintain the beauty of the aluminium corrugated composite plate.

3, durability is reinforced by the use of corrugated core composite material to enhance its durability.

4, light benign compared with the weight of other metal aluminum plate products, has superior light benign.

5. Good insulation and sound insulation. The air layer in the middle of the aluminum corrugated plate is separated by the panel, the bottom plate and the water corrugated core into many sealed cell rooms, which greatly limits the conduction of heat and sound waves, so that the plate has better insulation and sound insulation characteristics.

6, the aluminum corrugated composite board made of recyclable aluminum is 100% recyclable products.

7, machinability can be designed to facilitate cutting, joining, bending and other methods of processing.

Aluminum corrugated board specifications: according to the actual needs of customers according to the map processing.

The standard specifications are:

Length: arbitrary in the range of 10000mm

Width: 1220mm or 1500mm

Thickness: 4mm, 6mm, 8mm

Panel thickness: 0.8-1.5mm

Texture of material:

Aluminum corrugated plate is a kind of high strength aluminum composite plate which is composed of aluminum alloy plate and corrugated core by special hot-type high viscose film and automatic continuous thermal composite process.

Industry applications: building walls, interior decoration and other decorative areas.