Products

Aluminum honeycomb plate

Classification:

Aluminum honeycomb plate

Key words:

Introduction of aluminum honeycomb panel

Aluminum honeycomb board is a new kind of composite material developed by introducing advanced composite equipment from Germany and using hot melt adhesive. It overcomes the shortcomings of traditional honeycomb board such as brittleness of adhesive layer, low tear resistance, low impact resistance, poor workability and high cost, and thus opens up a new prospect of wide application of aluminum honeycomb board. Aluminum honeycomb panels have extremely light weight, very high lightness and rigidity, and no performance of decorative and long service life, so widely used, such as curtain walls, carriages, hulls, especially in construction, can withstand high wind pressure, meet the strict requirements of customers, but also has very good smoothness.

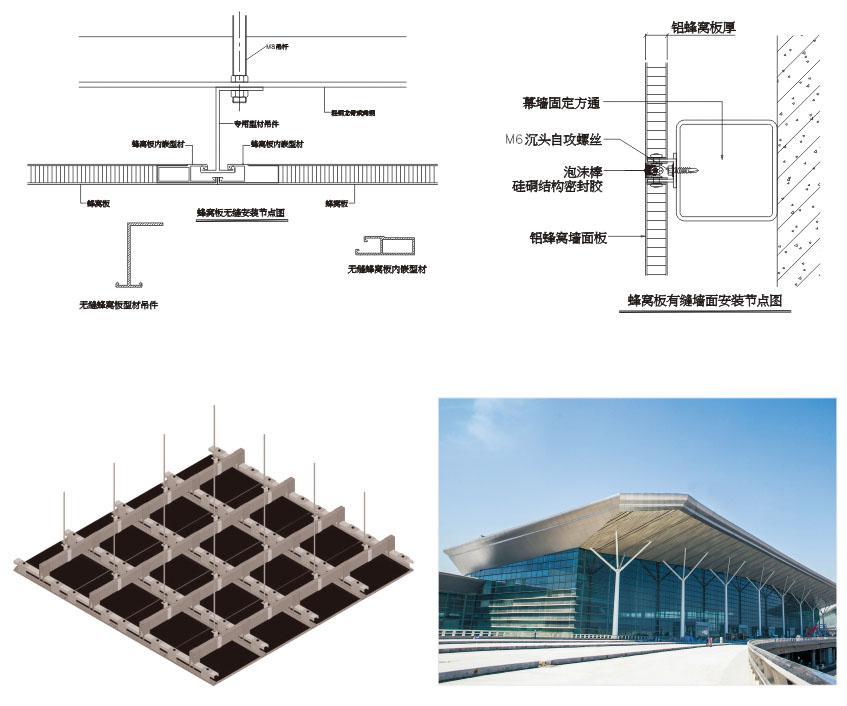

Application scope of honeycomb panels

Heat exchangers, energy absorption, rectifiers, aluminum honeycomb curtain panels, ceilings, partition panels, cars, boats, interior partitions, floors and exteriors, equipment enclosures, aviation, aerospace, panel furniture, screens, doors, packing boxes, pallets, electrostatic overhead floors, light-weight houses, billboards, computer graphics Board and so on.

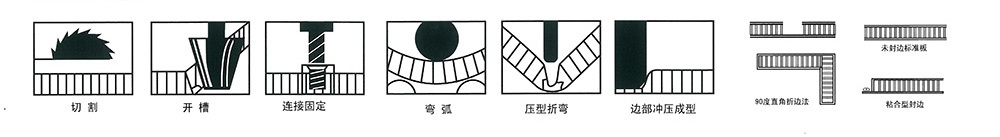

Honeycomb panel cutting map

Materials and technologies for honeycomb panels

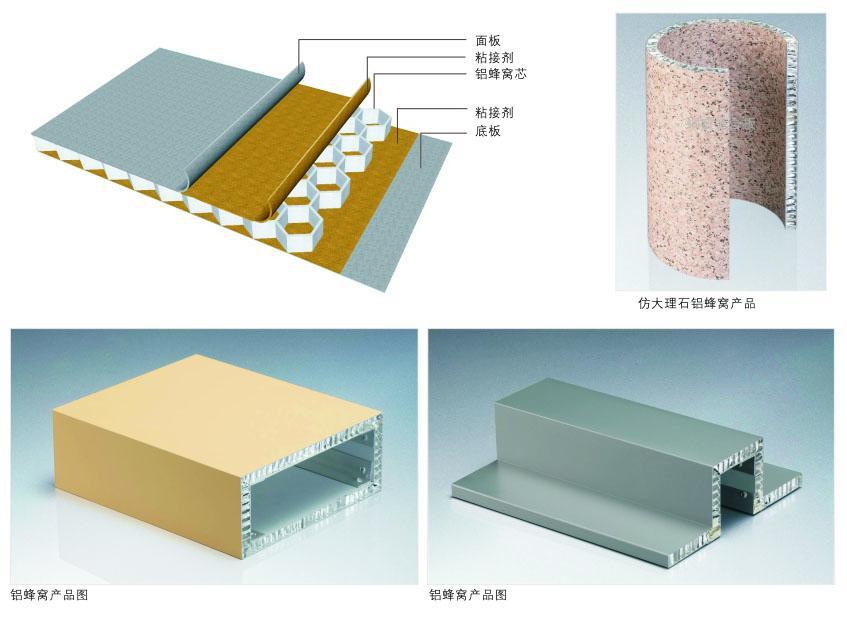

1. product materials

Aluminum panel: 3003H24 alloy aluminum plate or 5025H14 high strength alloy aluminum plate with thickness of 0.8-1.5mm is selected as the base material.

Aluminum floor: the thickness of the bottom plate is 0.5-1.0mm

Aluminum honeycomb: core material is hexagonal 3003H24 type aluminum honeycomb core, aluminum foil thickness is 0.04-0.07mm, side length is 5-6mm.

Adhesive: two component oxygen glue film and two component modified epoxy gum.

2. precoated plate

The coating used on the surface of aluminium honeycomb panel for curtain wall of "Holiday" brand is a one-off pre-rolled fluorocarbon polymer coating, which can effectively control the color difference and smoothness of the surface paint of the panel. The problem of coarse particle size in traditional coating process was successfully eliminated. The colors are uniform, delicate, soft and bright. Fluorocarbon polymer coatings, mainly composed of fluorocarbon resins of not less than 70% Kynar 500 or Hylar 5000, are the most stable durable terrace coatings with molecular structure. Products coated with fluorocarbon coatings can withstand UV radiation in the sun for a long time, industrial waste gas, acid rain and chemical erosion, can maintain long-term color stability and smooth coating cloth peeling, cracking, non-pulverization, etc.

Characteristics of aluminum honeycomb panels

Light weight, high strength, large rigidity, stable structure and good wind pressure.

"Hao Ruida" curtain wall aluminum honeycomb panel has been widely used in building exterior wall decoration. The honeycomb sandwich plate with the same stiffness weighs only 1/5 of the aluminum plate, the total thickness of the steel plate is 15 mm, the panel is 10 mm, and the base plate is 0.8 mm. The weight of the honeycomb sandwich plate is only 6 kg per square meter. The interconnected honeycomb cores, like innumerable I-shaped steel cores, are distributed and fixed in the whole panel. They are not easy to produce shear, can resist bending and compression, and their wind pressure is much higher than that of aluminum-plastic and aluminum veneer. Even if the honeycomb panels are very large, they can achieve extremely high flatness. "Holiday" aluminum honeycomb board with the smallest weight and maximum strength and deflection, is the incomparable characteristics of other materials, is currently the construction industry's preferred light material.

Sound insulation, heat insulation, fire prevention and shockproof functions are outstanding.

Because the honeycomb core in the aluminum honeycomb composite board is separated into many enclosed chambers, which prevents air flow, hinders heat and sound waves, and upheaves the sound source at 100-3200HZ.

Noise can reach 20-30DB, thermal conductivity is 0.1040.130W/M.k, energy absorption capacity of aluminum honeycomb panel is 150-3500KJ/M, is an ideal energy-saving material. In case of

The honeycomb panel avoids the noise when raindrops hit the aluminum veneer or aluminum-plastic panel during heavy rain.

The appearance is straight, colorful, elegant and clean.

"Holiday" brand curtain wall aluminum honeycomb board, different sizes have very high flatness, and has the advantage of easy deformation, the panel mainly uses fluorocarbon roll-coating aluminum plate. The most important point of fluorocarbon roll-coating aluminum plate is the use of continuous roll-coating process, aluminum plate coating is a one-off finish, product color, coating smoothness, reliable quality, can keep the building exterior wall color bright for a long time. After long-term exposure to the sun and rain or industrial waste gas pollution, it is obvious that the roll-coating plate is cleaner and brighter than the spraying plate, and has good adhesion and weatherability, is recognized as the world's first-class building materials.

Strong decoration, easy to install and fast.

The bottom panel of honeycomb panel can be made of different materials according to different requirements, such as aluminum plate, stainless steel plate, color steel plate and natural stone. The aluminum honeycomb panel of curtain wall is designed according to the site.

The size of the meter is processed in the factory. The sheet is bended around, and then formed by composite forming, then punched and hung up the ear, which is connected with the plate as a whole, so that the honeycomb hanging board after forming is more solid. Honeycomb plate can be made into flat plate, arc plate, L-shaped and U-shaped plate, full factory production, reliable quality, easy installation, fast.