Products

Aluminum profile

Classification:

Aluminium profile

Key words:

Aluminum profile product characteristics

1. base material

Product standard: GB/T5237.1-2000

Equipment characteristics: 3000 tons extruder 1, 1800 tons extruder 1, 1000 tons extruder 1, 800 tons extruder 1, 600 tons extruder 1

Product characteristics: extrudable circular 300mm of various traffic, electronic and mechanical industrial profiles and various components, unit, curtain wall profiles and decorative profiles (furniture profiles).

2. Anodizing (silver white, champagne, pure copper, true black, imitation stainless steel, titanium gold).

Product standard: GB/T523.7-2000

Process characteristics: full set of SanRex coloring power supply and electrolytic coloring process.

Product characteristics: uniform film thickness, high microhardness, good wear resistance, electrodeposited non-ferrous metal particles in the film hole pedicle solid, uniform, good light scattering.

3. Electrophoresis coating

Product standard: GB/T5237.4-2000

Process characteristics: full set of SanRex color power supply and HONNYLITE (Hani) electrophoretic paint and process.

Product features: electrophoretic composite film surface smooth, bright, high hardness, good wear resistance. At present, it can produce aluminum electrophoretic and color ivory electrophoresis.

4. Powder spraying

Product standard: GB/T5237.4-2000

Process features: full set of Swiss gold horse spraying equipment

Product Characteristics: Good adhesion, acid rain and alkali resistance, with the external wall decoration integration, fashion, elegant.

5, heat insulation and sound insulation aluminum materials.

Product standard: CENPrEN14024

Process features: the complete introduction of Muller rolling equipment in Switzerland and the adoption of the German "TECHNOFORM" and Italy

"AlfoSolare" glass fiber reinforced polyamide nylon 6.6 heat insulation strip.

Product Characteristics: Composite insulation aluminum has high mechanical strength, good heat insulation, sound insulation performance, good chemical corrosion resistance, fully in line with the building envelope heating coefficient requirements, is the world's doors, windows, curtain wall high-performance, high-grade products.

6. Fluorocarbon spraying

Product standard: GB/T5237.5-2000 AAMA20650-98

Process characteristics: a full set of introduction of Taiwan "Bai Fu" spray painting equipment

Product characteristics: good adhesion, withstand various climate corrosion, will not accumulate dirt, uniform and bright color, is the best surface treatment of aluminum products.

7. Deep processing workshop

It can make deep processing, welding, riveting, splicing and other processing for aluminum products.

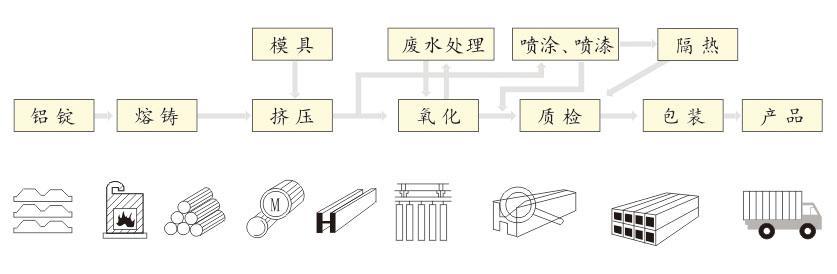

Production technology of aluminum profiles

Corrosion resistance

The density of aluminum profiles is only 2.7 g/cm 3, about 1/3 of that of steel, copper or brass (7.83 g/cm 3, 8.93 g/cm 3 respectively). In most environmental conditions, including air, water (or brine), petrochemical and many chemical systems, aluminum exhibits excellent corrosion resistance.

conductivity

Aluminum profile is often chosen because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly two times that of copper.

Thermal conductivity rate

Aluminum alloys have a thermal conductivity of about 50-60% of copper, which is good for making heat exchangers, evaporators, heating appliances, cooking utensils, and car cylinder heads and radiators.

Nonferromagnetism

The non-ferromagnetic properties of aluminum profiles are important features for the electrical industry and the electronics industry. Aluminum profiles are not self ignition, which is important for applications involving or touching inflammable and explosive materials.

Machinability

Machinability of aluminum profiles is excellent. In all kinds of deformed and cast aluminium alloys, as well as in all kinds of States after the production of these alloys, the machining characteristics change considerably, which requires special machine tools or techniques.

Formability

Specific tensile strength, yield strength, extensibility and corresponding work hardening rate dominate the allowable deformation.

Recovery

Aluminum has very high recyclability, and the properties of recycled aluminum are almost the same as that of native aluminum.